E-Commerce, Magento 2, Shopify, Shopware

Running an online store is like navigating a never-ending puzzle. Every day, you juggle fluctuating customer demands, storage limitations, and production costs. One wrong move, and you’re stuck with either too much inventory or not enough to meet demand. That’s where a strategic tool like MOQ (minimum order quantity) comes into play.

Imagine this: you’re a clothing retailer ordering t-shirts from a supplier. You’d love to order just enough to meet a short-term sale, but the supplier requires you to buy a minimum of 500 units. That’s your MOQ — the smallest number of units a supplier is willing to sell. While it may seem like an extra complication, MOQs are actually a crucial part of managing both sides of the supply chain, ensuring neither party takes on unnecessary risk.

MOQ meaning isn’t just about the supplier’s convenience. It’s a survival tool for e-commerce businesses. By setting a minimum order quantity, companies can avoid the pitfalls of high storage costs, low profitability, and inefficient production runs. It’s all about balance. While you want to offer your customers flexibility, you also need to ensure that your business stays profitable.

In today’s e-commerce landscape, understanding what is MOQ is becoming more important than ever. For merchants selling everything from handmade goods to electronics, MOQs are a key strategy in inventory management. They help streamline operations, optimize stock, and maintain profitability. Whether you’re just starting or looking to scale, what does MOQ mean for your business? Let’s find out.

Table of contents

- 1 MOQ Explained – A Critical E-Commerce Strategy

- 1.1 What Does MOQ Stand For?

- 1.2 Why Does MOQ Matter?

- 2 Unpacking the Benefits of MOQ

- 2.1 Maximizing Efficiency

- 2.2 Cost-Effectiveness

- 2.3 Inventory Optimization

- 3 Types of MOQ

- 4 Key Factors That Shape MOQ Decisions

- 5 Implementing MOQ in Major E-Commerce Platforms

- 5.1 Magento – Advanced Customization

- 5.2 Shopify – Simplicity with Third-Party Tools

- 5.3 Shopware – Powering Enterprise with Flexibility

- 6 How to Calculate MOQ for Your Business

- 6.1 Introduction to MOQ Calculation

- 6.2 The Calculation Formula

- 6.3 Balancing MOQ and Customer Expectations

- 7 MOQ in Action – Real Business Cases

- 7.1 Case Study 1: Wholesale Clothing – Bella+Canvas

- 7.2 Case Study 2: Tech Components – Digi-Key Electronics

- 7.3 Case Study 3: E-Commerce Shops – Tattly

- 8 Conclusion: Setting the Right MOQ for Your Success

MOQ Explained – A Critical E-Commerce Strategy

Below, we explain what MOQ is and why it is so important.

What Does MOQ Stand For?

MOQ, or minimum order quantity, is a term that defines the smallest amount of product a supplier is willing to sell. In simple terms, it sets the baseline for transactions between suppliers and retailers.

Take, for example, a local printing facility that specializes in custom t-shirts for small businesses and local bands. For each order, they have a minimum order quantity of 20 t-shirts. This isn’t just an arbitrary number; it’s driven by real-world costs, specifically the expenditure required to create a printing stencil or template for each unique design.

In this case, what does MOQ stand for? It stands for the break-even point where the facility can cover the cost of production while still making a profit.

So, MOQ meaning is straightforward: to cover the time and materials needed to prepare a design, the printer must produce at least 20 shirts. Printing fewer than that would make the setup cost — like creating custom stencils — too expensive, eating into the profit margin. Or the price of one unit would be much higher than a buyer can afford. Thus, by setting an MOQ, they ensure that both the business and the customer get the most value from the transaction.

From a business perspective, MOQs ensure that suppliers don’t end up making small, unprofitable orders that could hurt their bottom line. On the flip side, retailers use MOQs to maintain inventory efficiency, aligning stock with demand without overwhelming storage or eating into profits.

Why Does MOQ Matter?

For merchants, MOQs are a crucial balancing act. They ensure that each transaction is worth the operational costs, from shipping to storage. Without an MOQ, a business might have to fulfill small orders that aren’t worth the time or resources, driving up costs and reducing margins. But setting an MOQ that’s too high? That can scare off potential customers, especially smaller buyers who don’t want to commit to large purchases.

For the printer, setting a minimum of 20 t-shirts per order ensures that the time and materials invested in setting up each print run — like preparing a new stencil — are justified. Without an MOQ, they might have to fulfill small, inefficient orders that don’t cover production costs, resulting in financial losses.

From the customer’s perspective, the MOQ might seem like a barrier, but it also comes with perks, such as lower per-unit costs when ordering in bulk. Customers like local bands, who often need shirts for tours or selling online, understand that MOQ is essential to getting a reasonable price on custom gear. The right MOQ makes it possible for the printing facility to operate sustainably, while still offering competitive pricing for small businesses. Thus, it can help boost business sustainability, manage stock levels, and avoid the costly trap of excess inventory.

Unpacking the Benefits of MOQ

Managing a successful e-commerce business is all about striking the right balance between fulfilling customer demands and maintaining operational efficiency. Setting a minimum order quantity is one of the most effective ways to achieve this balance. MOQs help businesses streamline processes, optimize costs, and manage inventory more effectively. Below, we dive into MOQ benefits, explaining how it maximizes efficiency, enhances cost-effectiveness, and improves inventory management.

Maximizing Efficiency

Setting a minimum order quantity is a powerful tool for boosting operational efficiency. For businesses, especially those dealing with physical products, MOQs streamline the entire production process. By requiring customers to order a certain minimum, companies can consolidate production runs, which minimizes the frequency of setup and changeover times.

With a well-calculated MOQ, businesses can also minimize waste, as fewer small-batch runs mean less excess material and fewer inefficiencies in production.

In a printing facility, each custom t-shirt design requires a template or stencil to be created before production can even begin. This setup process takes time and materials, whether the customer orders 5 shirts or 50.

By enforcing a MOQ of 20 shirts per design, the facility minimizes the need to constantly switch out templates, reducing downtime and boosting production efficiency. Instead of setting up equipment for small, inefficient batches, the printer can focus on larger orders, ensuring that each run is streamlined and cost-effective.

Cost-Effectiveness

One of the key reasons businesses rely on MOQ is to ensure profitability. Every product comes with fixed costs — whether it’s raw materials, labor, or shipping. Without an MOQ, companies might have to fulfill small, unprofitable orders, which can quickly eat into margins. By setting a minimum, businesses cover these essential costs, ensuring that each order is profitable. Ultimately, it’s a balancing act between ensuring cost-effectiveness and maintaining customer satisfaction.

For instance, creating custom designs involves fixed costs, such as template production and labor for each print run. If the printing facility took on smaller orders — let’s say 5 shirts — it would be impossible to cover the costs of setup and production, leading to financial losses.

By setting an MOQ of 20 shirts, the facility ensures that each order generates enough revenue to cover these essential costs while still providing a fair price to the customer. In this way, MOQ is about balancing fixed costs to ensure profitability on every order.

Inventory Optimization

Effective inventory management is a constant challenge in e-commerce, and MOQs offer a solution. By setting a minimum order threshold, businesses can better predict demand, reducing the likelihood of overstocking or stockouts.

Overstocking ties up capital and storage space, while stockouts mean missed sales opportunities. With the right MOQ, businesses can maintain a smoother flow of products in and out of inventory, preventing these costly issues. They align supply with demand more accurately, ensuring a more optimized, cost-efficient inventory system.

While inventory might not seem like an issue in a printing facility that produces on demand, managing raw materials like inks, t-shirts, and templates can be challenging. An MOQ helps the facility predict how much material they’ll need for each order, preventing both overstocking and material shortages.

For example, knowing that each order must be at least 20 shirts, the business can order the correct amount of blank t-shirts and ink without worrying about waste. This leads to a smoother inventory flow and more effective use of resources, which is essential for managing costs and demand fluctuations.

Types of MOQ

Not all minimum order quantities are created equal. Depending on the industry and business model, MOQs can be structured in different ways to suit specific needs. Whether it’s a product-based MOQ, order-based MOQ, or tiered MOQ for bulk pricing, businesses use these strategies to maintain efficiency and profitability. Let’s dive into the different types of MOQs and explore how they are applied in various industries.

- Product-Based MOQ. A product-based MOQ is perhaps the most common type, where the minimum quantity is tied to a specific product, like in the example of a custom t-shirt printing facility that requires customers to order at least 20 shirts per unique design.

- Order-Based MOQ. An order-based MOQ applies to the total value or quantity of an entire order, regardless of the specific products being purchased. This type of MOQ is common in wholesale businesses. For instance, a wholesale supplier of kitchen appliances might require a minimum purchase of $500 per order, ensuring that smaller, less profitable orders don’t eat into their margins. In clothing wholesale, a supplier might set a minimum order of 50 units across different product lines, allowing retailers to mix and match styles while still meeting the MOQ.

- Tiered MOQ for Bulk Pricing. A tiered MOQ provides flexibility for customers who want to purchase in bulk, offering discounts based on higher quantities. This is common in consumer goods industries, where economies of scale drive down the per-unit cost. For example, in the printing industry, a t-shirt facility might offer reduced prices when customers order more than 50 or 100 shirts. In this scenario, the MOQ isn’t just a baseline — it’s an incentive for customers to order more to receive a better deal. The MOQ meaning here isn’t just about cost coverage; it’s a strategic pricing model designed to encourage higher volume sales.

Each industry has its own approach to MOQ, designed to fit the specific challenges and costs they face. Whether it’s product-based, order-based, or tiered for bulk discounts, understanding what MOQ is and how it’s used across industries is key to optimizing both business efficiency and customer satisfaction.

Key Factors That Shape MOQ Decisions

When setting a minimum order quantity, businesses must carefully consider a variety of factors that can significantly impact their operations. From supplier constraints to fluctuating demand, every decision about MOQ comes down to balancing profitability with operational efficiency. Let’s explore the key elements that influence how businesses determine their MOQ.

- Supplier Relationships. A business’s relationship with its suppliers often has the biggest influence on MOQ. Suppliers frequently impose their own minimums to cover production and shipping costs, which, in turn, affect the business’s MOQ. For example, a custom t-shirt printing facility might need to purchase blank shirts from a supplier that requires a minimum of 100 units per order. This supplier-imposed MOQ becomes a crucial factor in determining the facility’s own MOQ, as it needs to cover the costs of acquiring materials without overstocking.

- Demand Forecasting. Another key factor shaping MOQ is demand forecasting. Businesses must analyze customer demand patterns to avoid overproduction and excess inventory. For example, if a local printing facility regularly receives small, one-off orders from local bands, setting an MOQ too high might discourage sales, but setting it too low could lead to inefficient production. By forecasting demand, the business can strike the right balance, ensuring that they’re not overwhelmed with excess stock or facing shortages during high-demand periods. In seasonal industries, like fashion or holiday-themed products, demand forecasting becomes even more crucial to determine the right MOQ at different times of the year.

- Storage and Logistics. Storage capacity and logistics also play a huge role in determining MOQ. If a business doesn’t have the warehouse space to store large quantities of product, they might set a lower MOQ to ensure that stock is moving quickly. In the case of the printing facility, if they only have space for 1,000 shirts at any given time, they need to ensure that orders flow efficiently, neither overstocking nor understocking inventory. Additionally, shipping costs and lead times can influence MOQ decisions. Businesses often need to consider how much it costs to ship items in bulk versus smaller quantities. Long lead times from suppliers may also require businesses to set higher MOQs to avoid running out of stock.

Implementing MOQ in Major E-Commerce Platforms

Popular platforms like Magento, Shopify, and Shopware offer varying degrees of flexibility and customization when it comes to implementing MOQs. Let’s see what features are available.

Magento – Advanced Customization

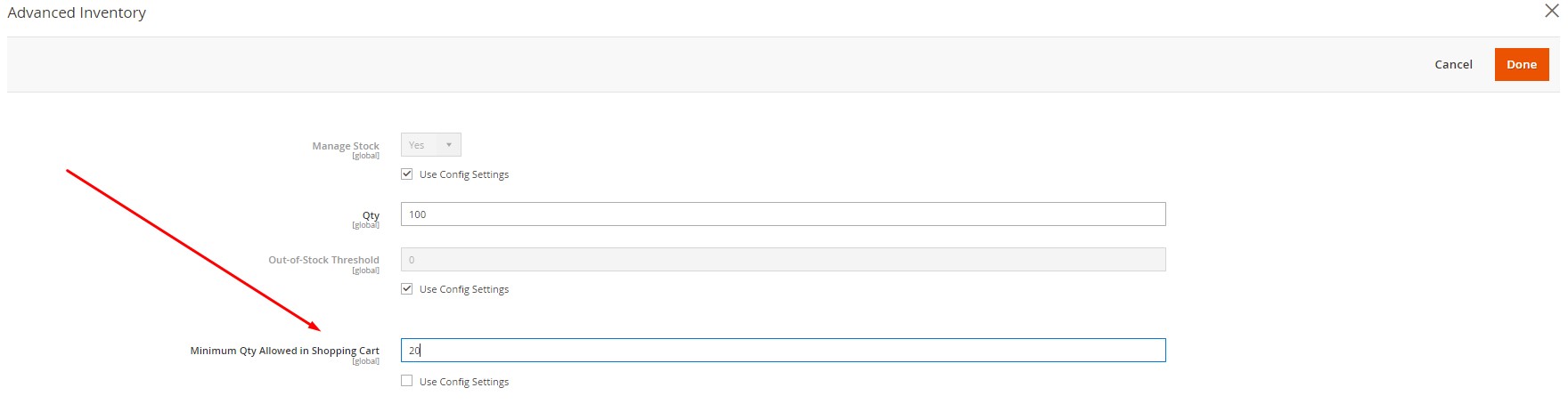

Magento is known for its deep customization options, making it an ideal platform for businesses looking to implement MOQs tailored to their specific needs. With its robust backend system, Magento allows merchants to set product-specific MOQs directly from the admin panel. Here is how to set MOQ in Magento 2 per product:

- Log in to your Magento Admin panel.

- Navigate to Catalog > Products.

- Select the product you want to edit.

- Under the Advanced Inventory tab, find the Minimum Qty Allowed in Shopping Cart setting.

- Enter the desired MOQ for this product (e.g., 20 units).

- Save the changes.

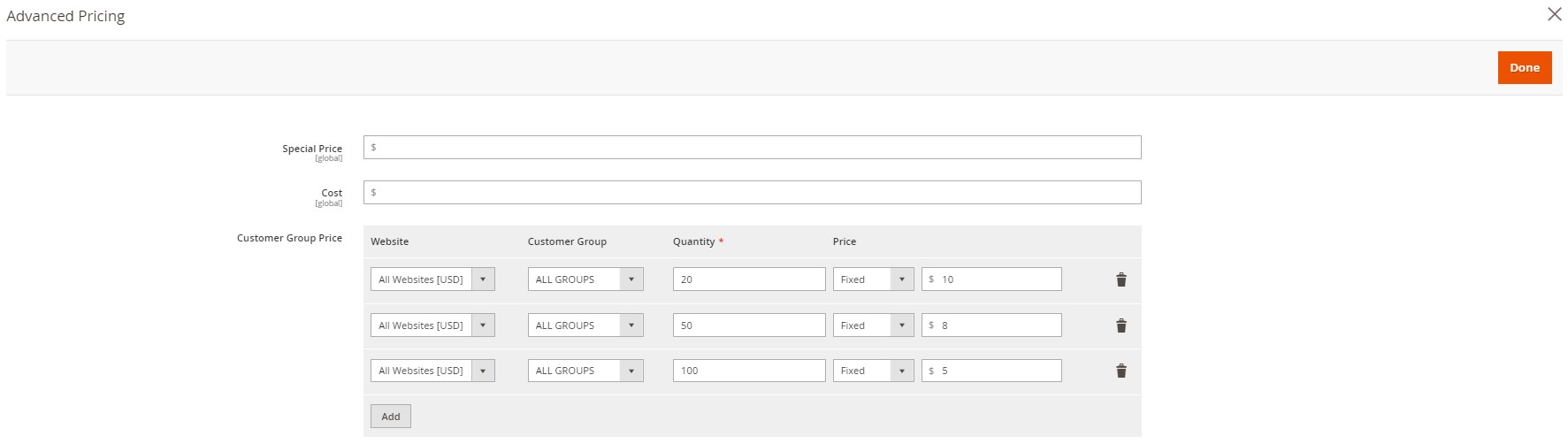

Magento’s flexibility also allows you to integrate tiered pricing with MOQs, which is particularly useful for bulk orders. For instance, if a customer orders 50 or more items, you can offer a lower per-unit price. This strategy encourages customers to buy in larger quantities, aligning perfectly with your MOQ strategy while offering them a discount for bigger purchases.

And if you need to follow MAP compliance, the platform also offers built-in features.

Shopify – Simplicity with Third-Party Tools

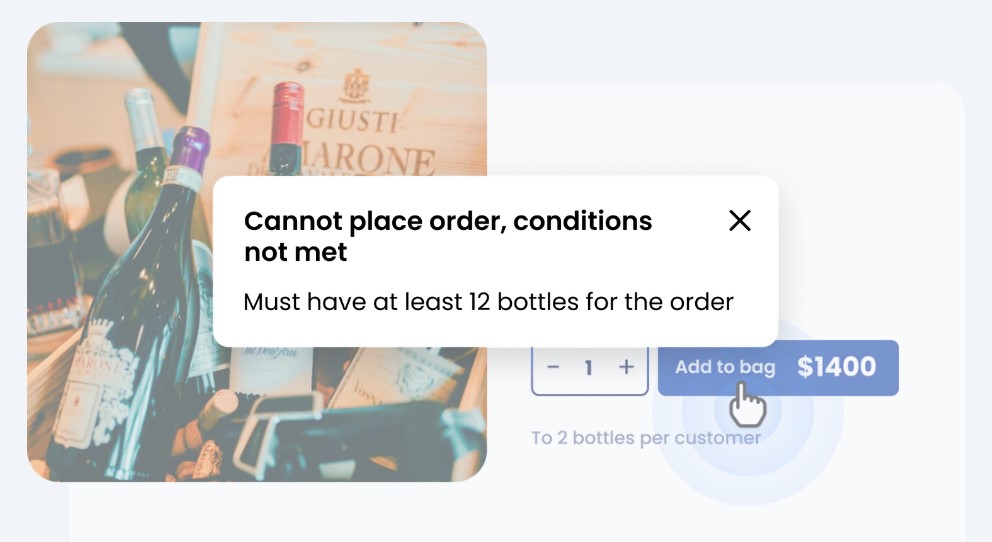

Shopify is known for its simplicity, but it doesn’t offer native support for setting MOQs. However, merchants can easily implement MOQ functionality by using third-party apps. One of the most popular tools for this is Order Limits, which allows you to set minimum quantities on a per-product or entire order basis. Here’s a simple guide to setting a minimum order quantity per product in Shopify using the Order Limits app:

- Install the Order Limits app from the Shopify App Store.

- Open the app and select Create a new limit.

- Choose whether you want to apply the MOQ to a specific product or across the entire order.

- Set your desired MOQ (e.g., 12 units per product).

- Save the settings, and the MOQ will automatically be applied to your store.

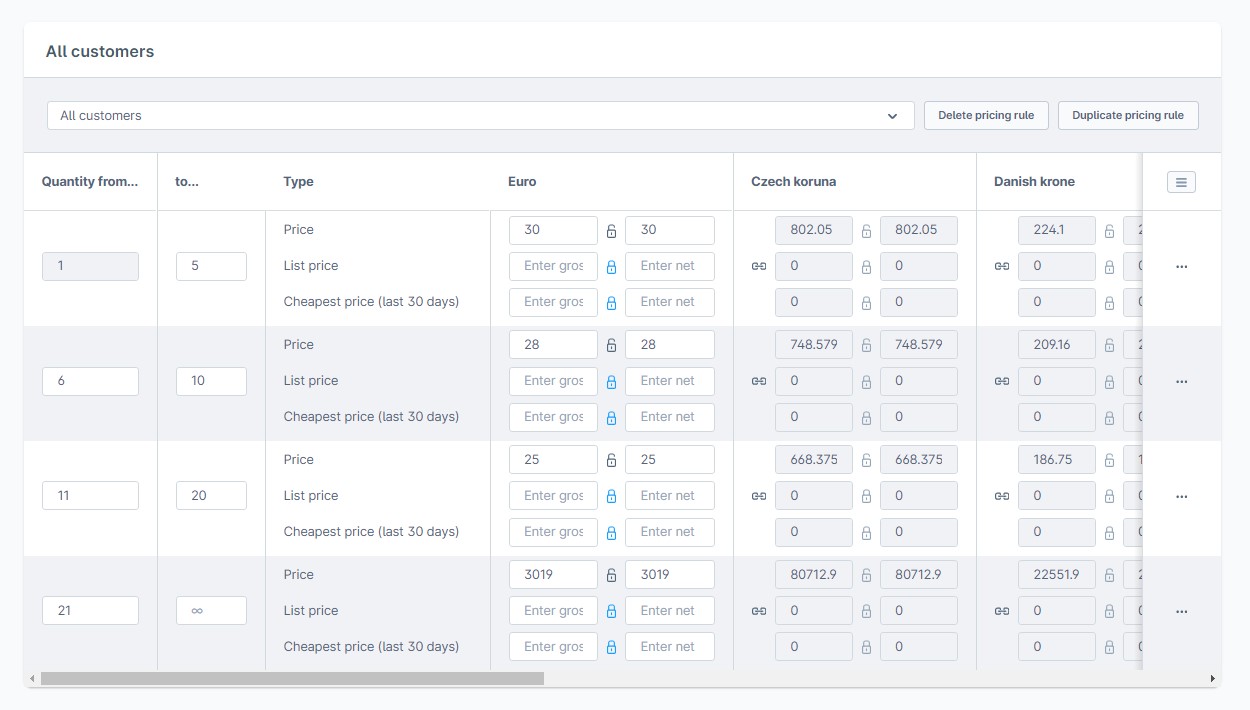

Shopware – Powering Enterprise with Flexibility

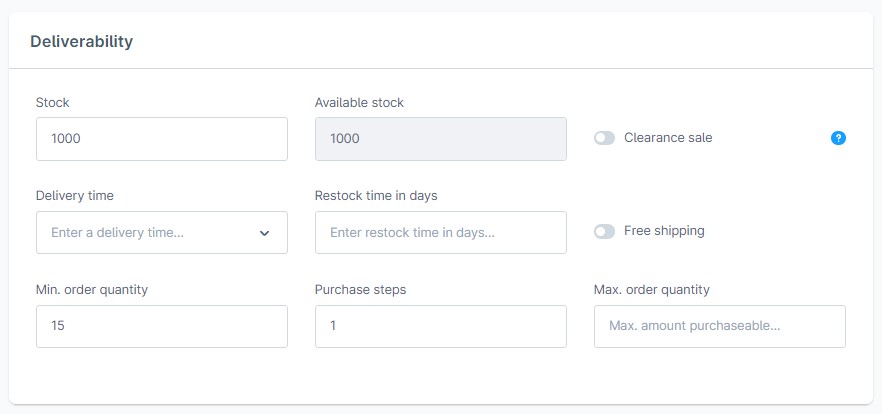

Shopware is built for larger-scale businesses, making it an ideal platform for those needing complex MOQ setups. With Shopware, MOQs can be implemented natively, offering deep customization options directly from the product settings. This is what you need to do to set MOQ in Shopware:

- In your Shopware Admin, go to Catalogues > Products.

- Select the product you wish to edit.

- Under the General/Deliverability section, you will find the Min. order quantity field.

- Enter your MOQ (e.g., 15 units).

- Save the changes.

Additionally, Shopware allows for bulk order options, where you can set different MOQs for various customer groups or offer tiered pricing similar to Magento. This gives businesses the ability to cater to different types of buyers, whether they’re purchasing small quantities or placing large, wholesale orders.

How to Calculate MOQ for Your Business

Now, that you know how to implement MOQ across different e-commerce platforms, let’s see how to calculate it. Determining the ideal minimum order quantity is a delicate balancing act — set it too high, and you risk alienating smaller customers; set it too low, and your profits may take a hit. To calculate the right MOQ, businesses need to consider production costs, demand forecasts, and supplier requirements.

Introduction to MOQ Calculation

The key to calculating a company’s ideal MOQ lies in understanding both operational costs and customer behavior. Several factors come into play: the cost of production, shipping, storage, and the minimum quantities your suppliers may impose.

Beyond these hard numbers, you also have to account for demand patterns. Does your customer base consist mainly of bulk buyers, or are they smaller buyers who might be discouraged by high MOQs?

The right balance ensures profitability without driving away potential business.

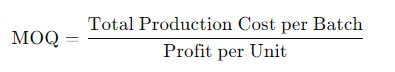

The Calculation Formula

A simple way to determine the right MOQ for your business is by using a basic formula that factors in production costs and supplier minimums. Here’s a framework you can use:

Where:

- Total Production Cost per Batch includes fixed costs like labor, materials, and machine setup.

- Profit per Unit is the amount you need to make on each product after covering costs.

For example, if it costs you $500 to set up a production run and you want to make $10 profit on each unit, your MOQ would be 50 units. This ensures you cover all costs while hitting your profit targets.

Balancing MOQ and Customer Expectations

While calculating the perfect MOQ ensures profitability, you also need to think about your customers. Setting your MOQ too high might deter smaller buyers, which can hurt overall sales. On the other hand, if your MOQ is too low, you could end up with small, inefficient orders that fail to cover production costs.

A practical strategy is to offer tiered pricing for bulk buyers, providing incentives for larger orders while still maintaining an MOQ that smaller customers can afford. This way, you can cater to both ends of the spectrum — customers looking for better deals on bulk orders, and those who need smaller quantities but are willing to pay a bit more per unit.

MOQ in Action – Real Business Cases

This section highlights how real-world businesses from wholesale clothing to tech manufacturing utilize MOQs to optimize their operations.

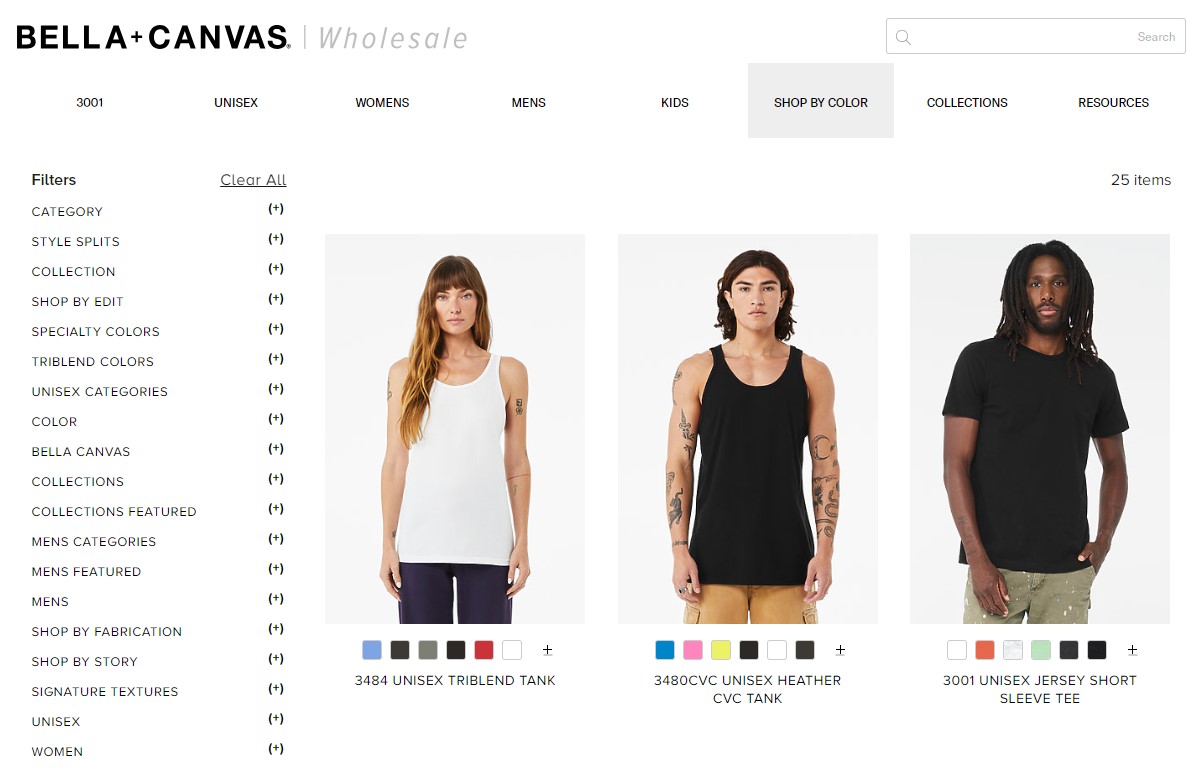

Case Study 1: Wholesale Clothing – Bella+Canvas

Bella+Canvas, a leading wholesale clothing company based in Los Angeles, has a unique MOQ policy. For domestic shipments, there are no minimum order quantities or values required, allowing retailers in the US to order as little or as much as they need.

However, for international orders, Bella+Canvas enforces a MOQ by the case, requiring larger bulk orders to justify the higher costs of international shipping and logistics.

This approach enables Bella+Canvas to cater flexibly to its US customers while managing the higher expenses associated with overseas shipments. The MOQ for international orders ensures that each transaction covers the cost of production, shipping, and customs, while also offering competitive pricing for bulk buyers abroad.

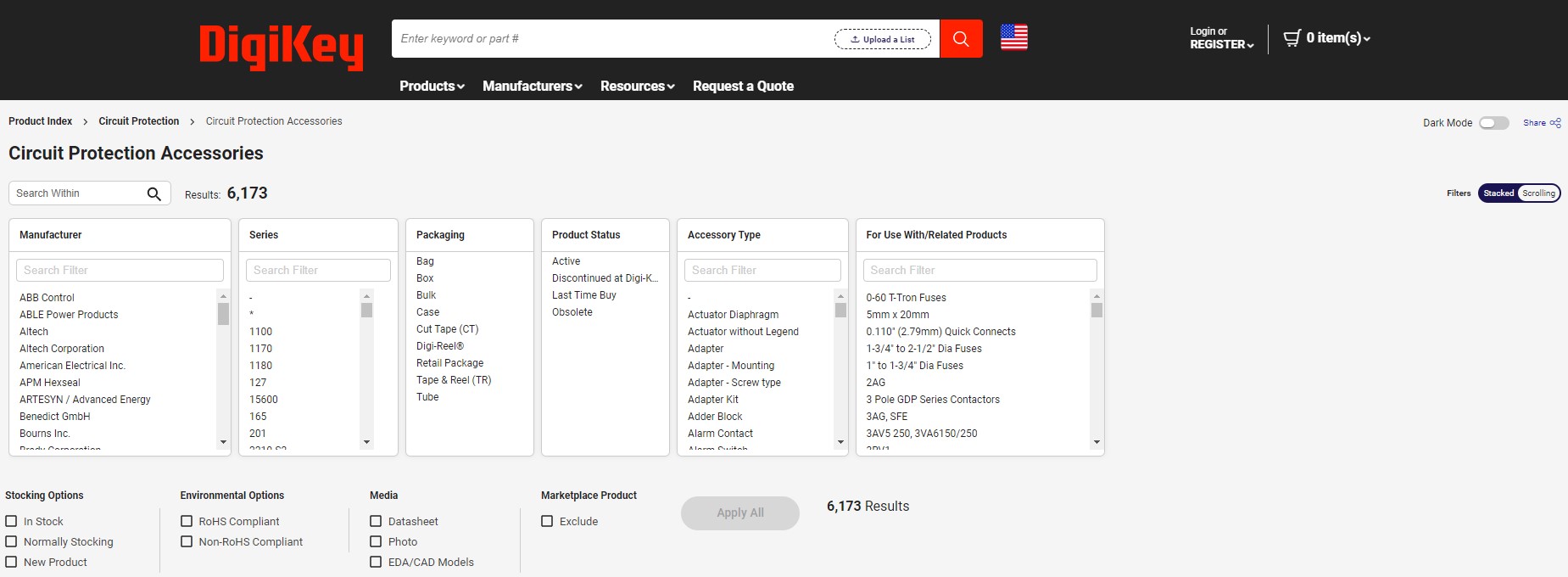

Case Study 2: Tech Components – Digi-Key Electronics

Digi-Key Electronics offers certain capacitors at 10 cents per unit when purchased individually. However, when a customer buys 50 capacitors, the price drops to 1.7 cents per unit or 85 cents total for 50. This bulk discount strategy incentivizes larger purchases by reducing the per-unit cost, making it more economical for customers to buy in higher quantities.

By using tiered pricing, Digi-Key uses MOQ to encourage customers to order in bulk, optimizing production runs and ensuring profitability. This approach helps Digi-Key maintain cost efficiency in both small and large orders, while offering clients the flexibility to scale up their purchases as needed.

Case Study 3: E-Commerce Shops – Tattly

Tattly is known for its high-quality temporary tattoos. It implements an MOQ of $200 for new retailers. This MOQ ensures that production, packaging, and shipping costs are covered, making each order profitable while still allowing small boutique retailers to carry their products.

As for direct-to-consumer sales, Tattly does not impose an MOQ, enabling individual customers to purchase small quantities.

By using different MOQ strategies for wholesale and consumer markets, Tattly successfully balances profitability without alienating smaller retailers or customers.

Conclusion: Setting the Right MOQ for Your Success

Implementing a minimum order quantity offers strategic advantages across industries and e-commerce platforms. From wholesale clothing to tech components, businesses use MOQs to streamline production, manage inventory, and ensure profitability. MOQs help balance production costs, optimize stock levels, and even incentivize bulk buying with tiered pricing. Whether you’re a small e-commerce shop or a large-scale manufacturer, finding the right MOQ ensures that each order is efficient and cost-effective, protecting your bottom line while offering value to your customers.

While MOQs are essential for maintaining profitability, they must be carefully tailored to meet the specific needs of your business and your customers. Setting an MOQ that’s too high can alienate smaller buyers, while one that’s too low may fail to cover operational costs. Striking the right balance allows businesses to thrive, offering flexibility where needed and ensuring each order adds value. The right MOQ isn’t just a number; it’s a strategic tool that, when applied thoughtfully, will drive long-term success.

Please enable JavaScript to view the comments powered by Disqus.

![iOS VPNs have leaked traffic for years, researcher claims [Updated]](https://whowillcare.net/wp-content/uploads/2022/08/ios-vpns-have-leaked-traffic-for-years-researcher-claims-updated-768x512.jpg)